Fatigue is the result of multiple repetitions of low-level stress applied to an object. Generally, fatigue happens in three stages:

Fatigue is the result of multiple repetitions of low-level stress applied to an object. Generally, fatigue happens in three stages:

- Crack initiation;

- Crack propagation; and

- Final fracture (otherwise known as, “The Breaking Point”)

The old adage “time is money” is a foundational concept in the vibration testing industry. Engineers want to test / fatigue products to failure so they can determine how long they are likely to survive in service and find ways to improve them. They do not, however, want to spend any more time than is absolutely necessary to reach these goals.

Putting Products to the Test

In response, the industry has developed technologies to help engineers break their products faster using increasingly sophisticated random vibration testing methods. A key requirement for these techniques is to increase the rate at which fatigue is induced into the Unit Under Test (UUT) without distorting the Power Spectral Density (PSD) profile to which it will be exposed in real world operation.

Vibration Research Corporation’s Fatigue Damage Spectrum (FDS) gives engineers a reliable way to accomplish this goal by increasing system energy. FDS is based on the principle of Miner’s Rule of Damage (i.e., fatigue damage will accumulate for a product until the life-dose of fatigue for that product has been met, at which point it will experience some failure).

Breaking it Down: An FDS Analogy

Let’s break down how fatigue damage works in the real world. As river water flows it slowly erodes away the banks of the river. Perhaps the water itself rubs across the soil and knocks particles loose. Or, perhaps the water carries other material (tree branches or sediment) that erodes away the riverbank. One way or another, the riverbank erodes. But, if the river has a faster current, it will erode away the riverbank more quickly.

River water with greater velocity has more energy to dislodge rocks and pebbles from the riverbank soil. Consequently, a faster flowing river will erode the riverbanks more quickly. If one knows the rate at which the soil erodes under normal river flow, one should be able to calculate the rate at which the soil will erode with a regularly faster flowing river. This natural phenomenon illustrates nicely the similar phenomenon of fatigue damage.

Looking at the Spectrum

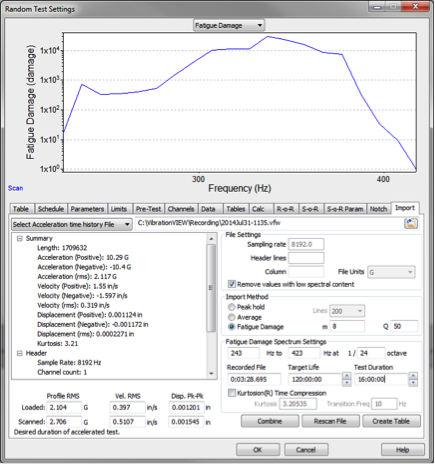

The FDS is essentially a plot of the amount of fatigue at every frequency in the spectrum that will bring the product to failure. With FDS, a test engineer can statistically simulate the end-use environment for a UUT (Figure 1).

Figure 1.

Once the end-use environment is simulated, the test engineer can accelerate a test to a desired test duration value (Figure 2).

Figure 2.

In addition, a test engineer can predict the life-expectancy (Target Life) of a product by adjusting the Target Life to produce a desired PSD and RMS value for a test (Figure 3).

Figure 3.

FDS is an innovative tool to simulate end-use environments and accelerate the breaking points of products. Ford Motor Company is one of many organizations using FDS to improve the cost-effectiveness of their vibration testing. How can you better test your products’ breaking points?

For more information:

Vibration Research

vrsales@vibrationresearch.com

616-669-3028

www.vibrationresearch.com